Scientific Purity. Cosmetic Brilliance.

Our team elevates your brand and quality with high-performance, rigorously controlled freeze-dried cosmetic services and reagents. Take advantage of Fortis freeze-drying expertise, gained over decades of knowledge supporting and manufacturing lyophilized diagnostic products. Fortis scientists work with your team to deliver your cosmetic formulation in a unique format that is preservative free and high-activity.

Stability, Activity, and Preservation

- Freeze-dried to retain potency of peptides, enzymes, proteins, and botanicals

- Supports clean, waterless formulations without added preservatives

- Instant rehydration, delivering fresh-dose activity

Format Innovation

- Spherical beads enable uniform dosing and consistent skin feel

- Lyophilized surface coating of custom applicators

- Bead and surface color customization for aesthetic appeal and product differentiation

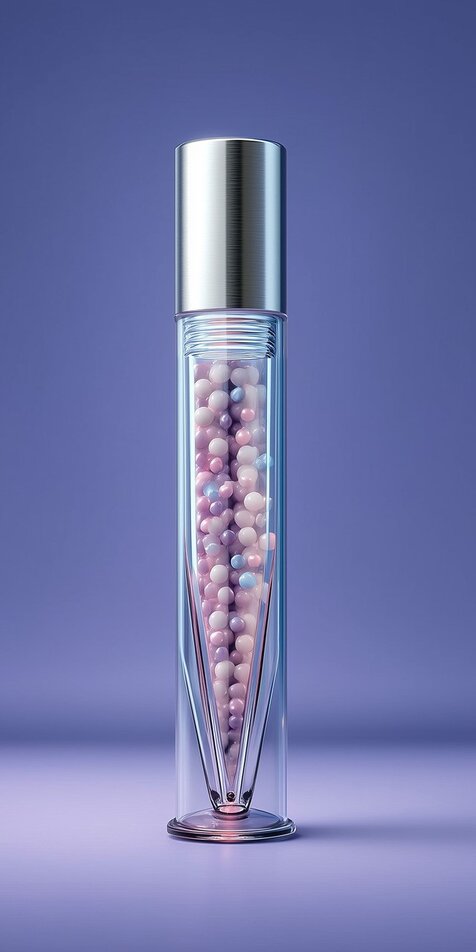

Freeze-dried Cosmetic Beads

We customize your formulations into freeze-dried cosmetic beads, ready for vials, dispensers, or bottles. Get precise dosing with beads size scaled between 1.5mm-5.00mm diameter. Freeze-dried cosmetic beads can be custom colored.

Freeze-dried cosmetic bead specifications:

- Reagent volume: 3-75µl

- Coloration: Natural plant-based colorant

- Selectable size range: 1.5mm-5.0mm +/- 0.5mm

Freeze-dried Cosmetic Surface Coating

Get your cosmetic formulation freeze-dried onto the surface of your choice. Great for applicators, swabs, sponges, spatulas, and more. Coating depth and coloration can be specified.

Freeze-dried cosmetic surface coating specifications:

- Coating depth: Variable

- Coloration: Natural plant-based colorant

- Surface materials: Must tolerate low temperatures

Custom Cosmetic Reagents

Our research team specializes in customizing proteins, peptides, antibodies and more. With in-house bioreactors, peptide and oligo synthesizers, and vector constructions, we can improve enzyme activity, stability, and likely improve your cost structures.

Custom reagent services for:

- Proteins/peptides

- Growth factors

- Biopolymers/bioactives

- Vitamins

- Probiotics

- Botanicals

- Excipients

Custom Cosmetic Manufacturing

Our facilities operate under production systems aligned with ISO 13485:2016 and cGMP, providing enhanced internal controls beyond ISO 22716 standards including: audit trails, CAPA, supplier management, product design and development, extensive validation, risk management,, and controlled environments. These systems are voluntarily adopted to ensure consistently high purity and quality products.

Freeze-dried cosmetic manufacturing services Include:

- Procurement

- QC/QA

- COA or other documentation

- Packaging

- Warehousing

- Shipping and logistics

Why Use Fortis for Freeze-Dried Cosmetic Manufacturing

| Factor | The Fortis Edge |

|---|---|

| Freeze-dried beads | With manufacturing capacity of over 2M freeze-dried beads per month, we have the capacity and experience |

| Rapid prototyping | In most cases, we can ship you freeze-dried prototypes within 10 days receipt of your formulation |

| Quality | Production systems aligned with ISO 13485:2016 and cGMP, providing enhanced internal controls beyond ISO 22716 standards |

| Redundancy | Manufacturing sites in United States and Canada |

| Customized with science | Our chemists and biologists can enhance stability and activity of your product |

FAQs

Let's Create Together!

Please fill the form below and one of our experts will reach out to you. Thank you for considering our partnership. We look forward to serving you.